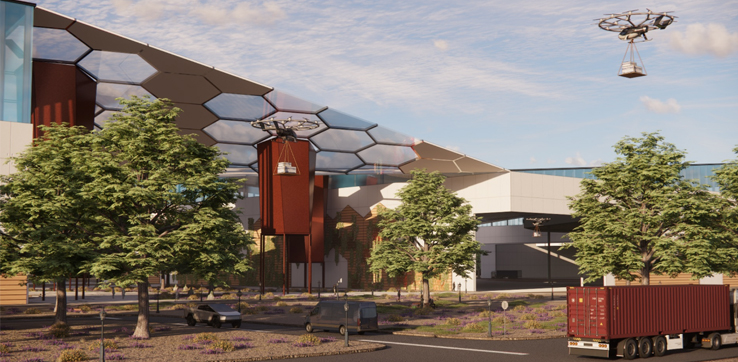

The last few years have been a catalyst for the already rapidly growing shipping industry and the need for Material-Handling Equipment (MHE).

First off, what is Material-Handling Equipment? Material-Handling Equipment is the mechanical equipment used for the movement, storage, control, and protection of products throughout the distribution process. Reference our previous blog on Design Considerations for Warehouse Automation for information about the individual systems. The storage component alone is comprised of dense racks stacked with product, typically 40 feet high. In many cases lately we’re seeing racks extending to 60 or 70 feet high, continually pushing the envelope for the volume of our fulfillment centers. These machines are not intended for human interaction with product. They are densely packed rows of product utilizing robotics for picking, sorting, and stocking.

As architects, we know how to design buildings for people, but the industry is demanding new skills to design for large machinery and robotics. We’ve got you covered and would like to share what we have learned about architectural and engineering coordination when it comes to Material-Handling Equipment.

Take a look at this slideshow for the design considerations related to MHE:

At the beginning of every project, we identify the correct internal team to fit the project type and requirements. This varies project to project and is important to accomplish our project goals and meet project budgets. Hand in hand with selecting a project team, intentional scheduling for the design process, and keeping the team on the same page aids in team efficiency.

Finally, streamlined coordination between the disciplines and vendors is crucial to the success of projects containing cutting-edge MHE. We achieve this by starting on the right foot with everyone working on the same software platform for 3D modeling. This typically involves Revit alongside platforms like 3D AutoCAD, Navisworks, or Vectorworks, with models detailed at a machine manufacturing level of detail for the MHE. We have found that it is extremely beneficial for all parties to contribute with 3D information to identify conflicts within the complicated and intermingled systems. Furthermore, we coordinate all modeling utilizing BIM cloud sharing to see real-time updates between consultant models which assures that everyone is working with the latest and greatest information. In addition to visual coordination achieved through 3D collaborative modeling, we create a framework of checks and balances for the project team and set up touchpoints for consistent reference throughout the project. Our larger industrial projects can require upwards of 15 specialized teams, so it is imperative to keep everyone included and on the same page.

Through our years of working on industrial building design, these are just a few of the methods we have discovered to keep our projects well-coordinated and on track. Our experience, along with our utilization of the latest technology and forward thinking can help your industrial projects be successful.